Understanding the Importance of Construction Equipment Rental

Construction projects, whether large-scale infrastructure developments or small commercial builds, rely heavily on the availability and effective use of machinery and equipment. Traditionally, owning construction equipment might have seemed like a strategic investment, but today, many contractors and project managers recognize the significant advantages of choosing construction equipment rental. Rental services provide flexible access to the latest technology and machinery, reducing upfront capital expenditures and ensuring projects stay on schedule and within budget. This shift towards rental solutions stems from evolving industry demands for agility, cost-effectiveness, and access to state-of-the-art equipment, factors that are critical in competitive markets like the UK.

Benefits of Renting vs. Buying Construction Machinery

While owning construction equipment can offer a sense of control and long-term availability, it often entails substantial financial outlays, maintenance responsibilities, and storage issues. Conversely, renting presents multidimensional benefits that are increasingly appealing:

- Cost Efficiency: Renting eliminates large capital investments and reduces expenditures related to maintenance, repairs, and depreciation. Contractors pay only for the usage period, transforming capital expense into operational expense.

- Access to Advanced Equipment: Rental companies continually update their fleets, allowing users to access the latest high-tech machinery, eco-friendly options, and specialized tools without additional costs.

- Flexibility and Scalability: Rental arrangements can be tailored to project timelines, scales, and phases. This flexibility enables contractors to scale equipment up or down as project needs evolve without financial penalties.

- Minimized Storage and Maintenance Burdens: Equipment remains with the rental provider, alleviating space constraints and maintenance logistics on-site.

- Reduced Risk and Obsolescence: Rental agreements mitigate risks associated with equipment depreciation, obsolescence, and technological mismatches, ensuring optimal productivity.

Key Types of Equipment Available for Rental

The UK construction industry benefits from an extensive array of equipment, tailored to diverse project requirements. These include fundamental machinery, power tools, safety equipment, and specialized units:

Earthmoving Equipment

Excavators, loaders, backhoes, and bulldozers form the backbone of earthworks, enabling efficient excavation, trenching, and material movement.

Compaction and Ground Preparation

Plate compactors, rammers, rollers, and vibroplates ensure stability and durability for foundations, pavements, and structures.

Concrete and Masonry Tools

Concrete mixers, power floats, poker vibrators, and formworks support the precise laying of concrete and masonry works, crucial for structural integrity.

Lifting and Access Equipment

Scissor lifts, cherry pickers, and telehandlers facilitate safe and efficient working at height, essential for façade works, roofing, and electrical installations.

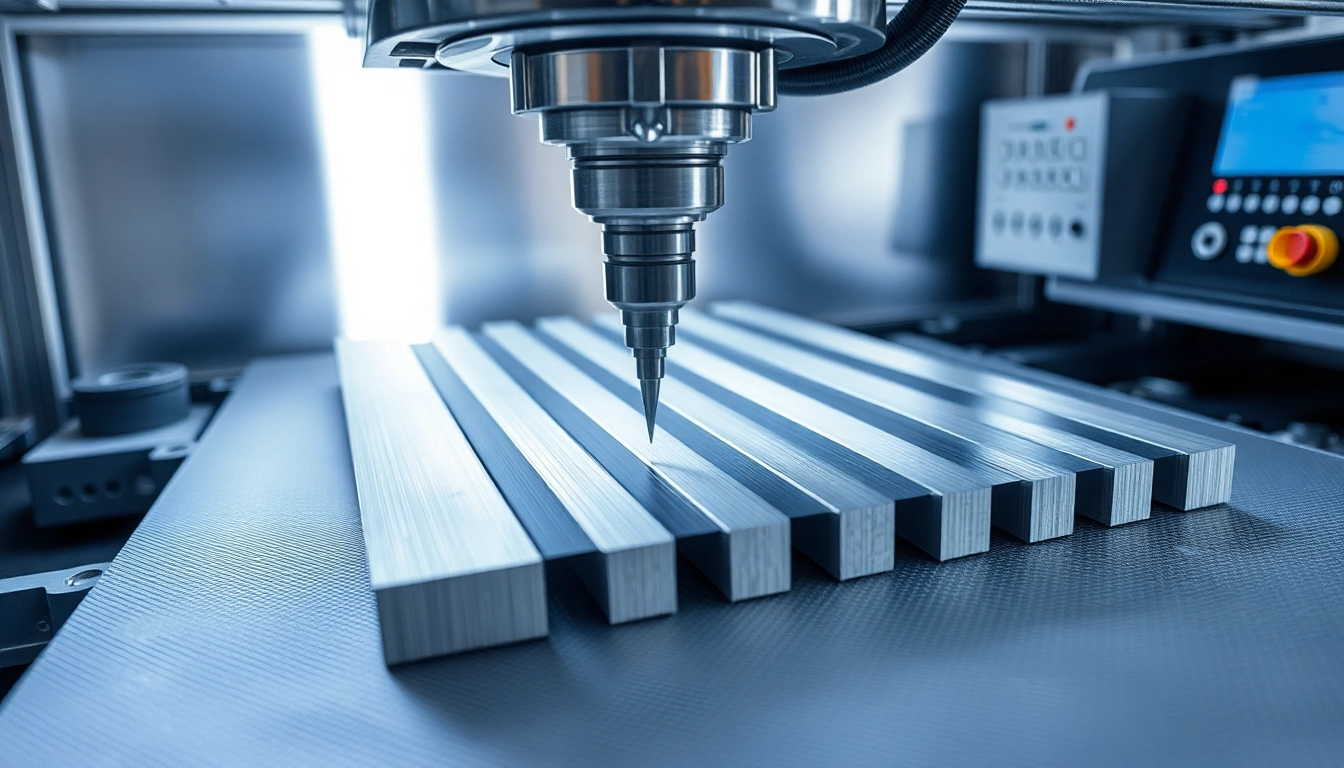

Power Tools and Handheld Equipment

Generators, drills, saws, and cutting tools support various on-the-go tasks, from carpentry to electrical setup.

Safety and Site Management

Barriers, scaffolding, site lighting, and environmental controls ensure safety standards and compliance compliance amidst dynamic construction environments.

Impact on Project Costs and Timelines

Integrating rental equipment into construction workflows significantly influences project economics and timelines. Cost control begins with reducing initial capital outlay and ongoing maintenance expenses. Moreover, rental providers often offer rapid deployment and reliable maintenance support, leading to minimal downtime and enhanced productivity.

Effective utilization of rental machinery allows for meticulous scheduling, aligning equipment availability with project phases. This synchronization minimizes delays caused by equipment shortages or breakdowns. For example, scheduling a fleet of excavators for a specific contract phase ensures continuous workflow, avoiding costly idle periods.

In comparison, equipment ownership may entail idle periods, depreciation costs, and asset management complexities that inflate total project costs and risk delays. Therefore, rental strategies not only optimize expenditure but also sustain project momentum, crucial for competitive bidding and timely project delivery.

Choosing the Right Construction Equipment Rental Partner

Factors to Consider When Selecting a Rental Provider

Partnering with a reputable rental provider is paramount for project success. Key factors to evaluate include:

- Range and Availability of Equipment: Ensure the provider offers a comprehensive fleet of modern machinery matching project specifications and timelines.

- Rental Terms and Flexibility: Review rental durations, cancellation policies, and options for extending or upgrading equipment.

- Pricing Transparency: Seek clear, competitive pricing with detailed breakdowns to aid accurate budgeting.

- Delivery and Logistics Capabilities: Confirm the provider’s ability to deliver, install, and retrieve equipment efficiently, especially for geographically dispersed sites.

- Customer Support and Service: 24/7 support, on-site assistance, and rapid response to maintenance issues help prevent project disruptions.

- Reputation and Client References: Research provider reviews, case studies, and client feedback within the industry.

Quality Assurance and Equipment Maintenance

Operational safety and efficiency hinge on the quality and condition of rental machinery. Leading rental companies implement stringent quality control standards and regular maintenance routines. Equipment undergoes routine inspections, testing, and prompt repairs to meet safety regulations. Transparent maintenance logs and certifications assure clients that machinery is reliable, reducing the risk of breakdowns during critical construction phases.

Ease of Delivery, Setup, and Support Services

An effective rental partner offers seamless delivery and setup services, minimizing site disruptions. Pre-delivery inspections ensure machinery meets safety standards and project specifications. Ongoing support includes technical assistance, operator training, and troubleshooting. Establishing clear communication channels guarantees that any issues are promptly addressed, maintaining project momentum.

Best Practices for Renting Construction Equipment Effectively

Assessing Project Needs and Equipment Specifications

Before committing to a rental, conduct a thorough assessment of project requirements. Collaborate with engineers and site managers to define the machinery specifications, capacity, and features necessary at each project phase. Use detailed scope documentation and equipment surveys to avoid under- or over-allocating machinery, which can lead to inefficiencies or unnecessary costs.

Scheduling Rentals for Maximum Flexibility

Develop a detailed equipment rental schedule aligned with project milestones. Consider factors such as lead times for delivery, equipment availability, and potential project changes. Flexible rental agreements, including options for short-term or seasonal rentals, help adapt to unforeseen project adjustments while maintaining cost control.

Ensuring Safety and Compliance on Site

Regular safety briefings, operator training, and adherence to local regulations are critical. Rental providers often offer training programs and safety documentation, ensuring operators are competent and compliant. Routine inspections and maintenance further mitigate hazards, fostering a safety-first culture that safeguards workers and reduces liability.

Maximizing ROI from Construction Equipment Rentals

Utilizing Latest Technology and Modern Machinery

Investing in state-of-the-art equipment enhances productivity, accuracy, and safety. Modern machinery integrates advanced features such as telematics, GPS tracking, and fuel efficiency systems that facilitate better management, real-time performance monitoring, and cost savings. For example, telematic data helps optimize equipment utilization, reduce idle times, and schedule predictive maintenance.

Training Staff to Operate Equipment Safely

Comprehensive operator training minimizes risks, improves operational efficiency, and extends machinery lifespan. Well-trained operators are adept at maximizing equipment capabilities while adhering to safety standards, reducing accident rates, and preventing costly damages.

Tracking Equipment Performance and Maintenance

Implement asset management systems to monitor equipment condition, usage hours, and maintenance schedules. Data-driven insights support predictive maintenance, avoiding unexpected failures and prolonging equipment lifespan. This proactive approach yields better return on investment and ensures consistent project progress.

Future Trends in Construction Equipment Rental Industry

Emerging Technologies and Green Equipment

The industry is witnessing a shift towards electric and hybrid machinery that reduce emissions and operational costs. Innovations such as remote operation, autonomous machinery, and IoT integration improve safety, efficiency, and environmental compliance.

Flexible Rental Models and Digital Platforms

Digital platforms streamline the rental process through online booking, real-time inventory management, and remote support. Flexible rental models such as pay-per-use, subscription services, and shared ownership are gaining popularity, offering tailored solutions to diverse project needs.

Market Growth and Opportunities in the UK

As UK infrastructure projects expand, demand for rental equipment continues to rise. Government initiatives like the UK’s focus on renewable energy and urban development fuel opportunities for equipment providers specializing in sustainable and innovative machinery. Rental companies that embrace digital transformation and green technology will position themselves competitively in this dynamic market.